Boron Carbide (B4C) Thin Film Coating is a very wear resistant coating. It is applied < 250F at 1.5-3 microns thick. It is a great solution when a hard, ultra lubricious coating is needed.

Key Benefits and Uses of Boron Carbide PVD Coating:

-

B4C prevents galling in wear components, forming, punching, and stamping applications.

-

B4C is extremely hard and its adherence is as strong as the base material itself.

-

B4C provides constant lubrication right where it’s needed when it’s needed. In fact, B4C has a wicking property where oil is attracted to the coating.

-

Will not alter the surface finish after the part has been coated. A polished finish stays polished!

-

Will not affect the metallurgy of the part. Will not anneal like a CVD coating will.

-

1-3 µm thickness

-

4500 Vickers HK hardness

-

Coefficient of friction: less than 0.4

-

Operates at a maximum temperature 1000°C

-

Color: Gray/Black

-

Will outlast Titanium Nitride by 3X

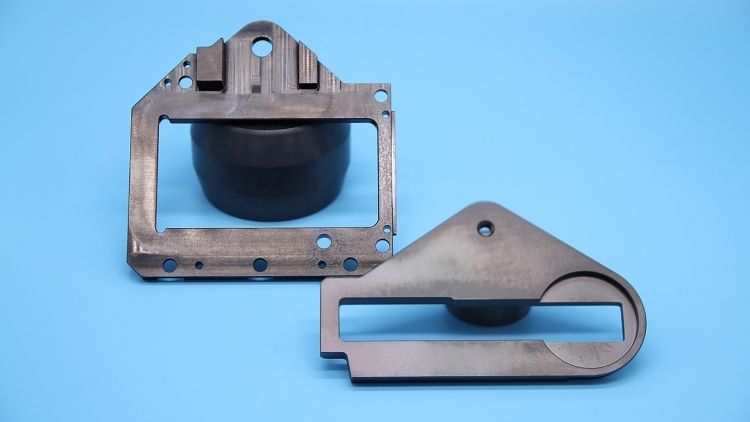

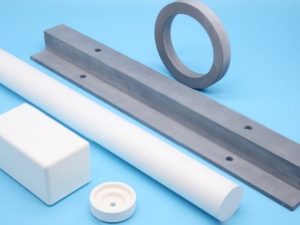

This unique coating has been used to coat:

-

gun drills

-

sliding wear parts in oilfield industry

-

gears

-

cold heading dies

-

forging dies

-

injection molds

-

form tools

-

wear parts