Ceramic Bearings are typically comprised of Zirconia, Alumina, tungsten carbide, or even Silicon nitride. These ceramics are ultra-hard with a Rc>90. Couple the high hardness with a low coefficient of friction and ceramic bearings exhibit long life and typically minimize the wear on the shafts running against the bearing.

Send us your application details and using our 30+ years of ceramic expertise, we will help you determine the right ceramic for your application.

Related products

-

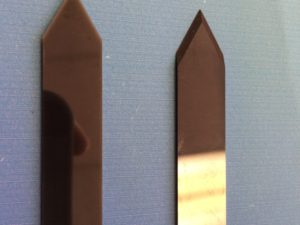

Ceramic Technologies offers a line of ceramic capsule blades used to trim hard capsules. Made with high purity HIP zirconia, our blades offer high strength…

-

Ceramic nozzles are typically made from low cost alumina, tungsten carbide or high performance Silicon nitride. Ceramic nozzles are used in industries like the sand…

-

Silicon nitride offers one of the best combinations of toughness and hardness of commercially available ceramics. In addition, its low thermal expansion coefficient offers superb…