Silicon nitride offers one of the best combinations of toughness and hardness of commercially available ceramics. In addition, its low thermal expansion coefficient offers superb thermal shock resistant compared with most other ceramics. Complex geometries can be made with sintered material. The material also exhibits low density, high temperature strength, excellent wear resistance and good facture toughness. Common applications include:

-

Diesel engine glow plugs

-

Rocker arm pad

-

Ceramic ball bearings

-

Check Valves for Oil Well Applications

-

Resistance Welding Fixtures

-

Sand blasting nozzles

-

MWD wear parts in Oil Well Drilling

-

Poppet valves

-

Guide rollers for steel rods and cable

-

Molten Aluminum Nozzles and trim

-

Valve Trim

Category: Ceramic Technologies Product Catalog

Related products

-

Ceramic Bearings are typically comprised of Zirconia, Alumina, tungsten carbide, or even Silicon nitride. These ceramics are ultra-hard with a Rc>90. Couple the high hardness…

-

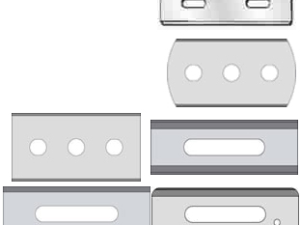

Ceramic Technologies introduces the newest improvement in Razor blade technology in 15 years. The U.S. made Tri-Coat Razor Blade is a steel blade with 3 layers of…

-

Ceramic Technologies introduces an improvement in reliability and consistency in the US made Ceraslit ceramic coated razor blade. Get the performance of a ceramic coated…