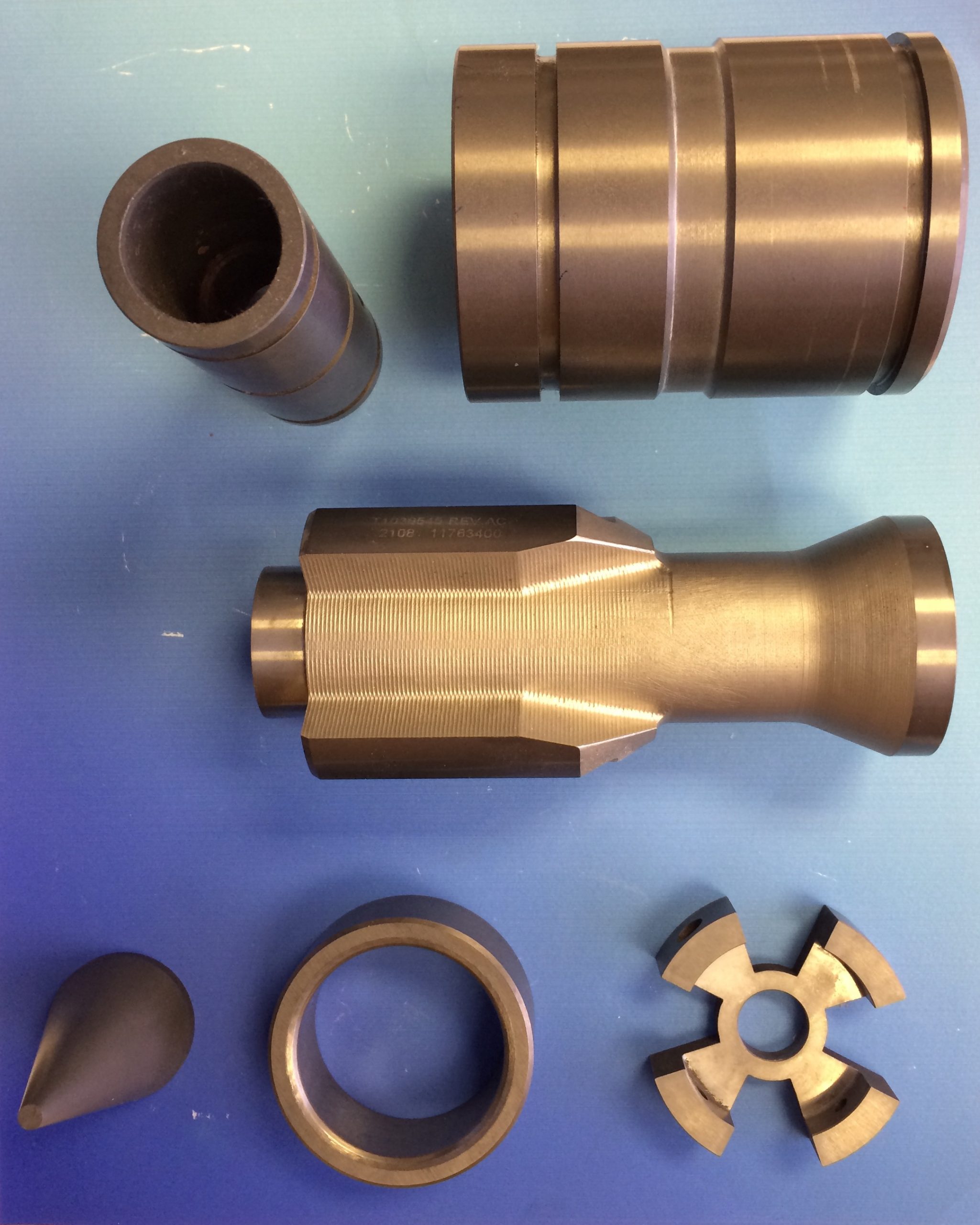

Ceramic Technologies specializes in custom nickel and cobalt binder tungsten carbide wear parts. We make bushings,

sleeves, cones, rods, tubes, rings, downhole oilfield parts, orifices, poppet tips and many others.

Our primary materials are a 12% Cobalt/88% WC matrix and a 6% Ni/94% WC matrix.

We also offer grinding services at our shop in Austin TX. We can slice and dice rods, plates and tubes. We can also centerless grind,

Surface grind and Blanchard grinding along with CNC 5 axis grinding.

Related products

-

Sintered Alpha silicon carbide is one of the hardest, most corrosion resistant ceramics commercially available. With no free silicon, this material resists even the strongest…

-

Zirconium Oxide (Zirconia) is the toughest ceramic commercially available. We actually have a hammer made out of this ceramic. This high-strength material exhibits excellent wear…

-

Silicon nitride offers one of the best combinations of toughness and hardness of commercially available ceramics. In addition, its low thermal expansion coefficient offers superb…