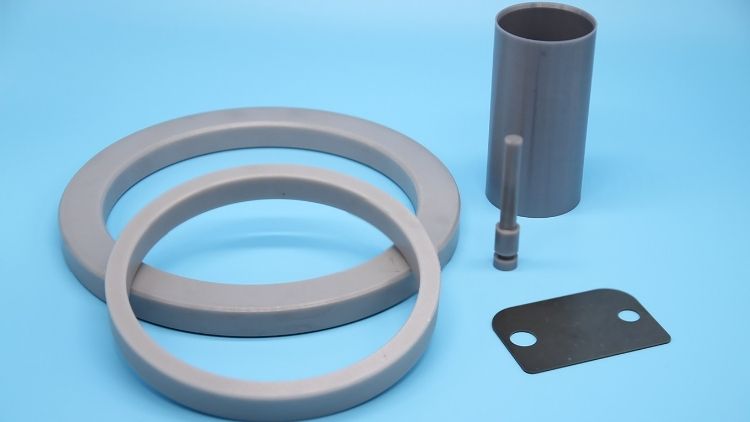

Our fine-grained sub-micron yttria stabilized zirconia is a great material for zirconia ring applications. Zirconia pad printer rings, Piston wear sleeves and zirconia bushings outperform tungsten carbide and any hard-facing coatings. The low coefficient of friction that zirconia offers minimizes wear from sliding friction. In addition, zirconia offers superb corrosion resistance, which is the main reason it will outperform tungsten carbide in oil service applications. The ceramic is easily press fit or heat shrunk into steel bodies to provide a long wearing system.

Other grades such as HIP zirconia or MgO stabilized zirconia are also available. Shoot us an email with any questions or to ask us to quote your zirconia ring requirements.

Related products

-

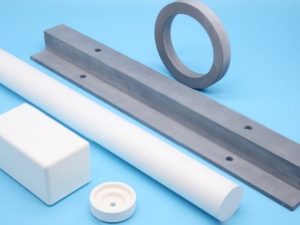

Our 90-99.5% alumina ceramics offer exceptional wear resistance at a reasonable price. Alumina is characterized by ultra high hardness, excellent insulating capabilities, and high temperature…

-

Sintered Alpha silicon carbide is one of the hardest, most corrosion resistant ceramics commercially available. With no free silicon, this material resists even the strongest…

-

Boron Nitride is a high temperature, lubricious ceramic. It offers excellent electrical resistance, chemical stability and wet ability.